Our Services

I. 2024-25 Lean Jax Training Workshops

Downloadable Workshop Overviews

Training Workshop Costs

Lean Jax Members: Included in annual membership dues.

Non-Members: $75-$150 per attendee per session.

II. Lean Leadership Webinar Series

✅ Learn from experienced Lean leaders from a myriad of industries.

✅ At least one (1) session each month via Zoom.

Lean Leadership Webinar Series Cost

Lean Jax Members: FREE for unlimited attendees.

Non-Lean Jax Members: $50 per attendee.

III. Lean Leader Meetings

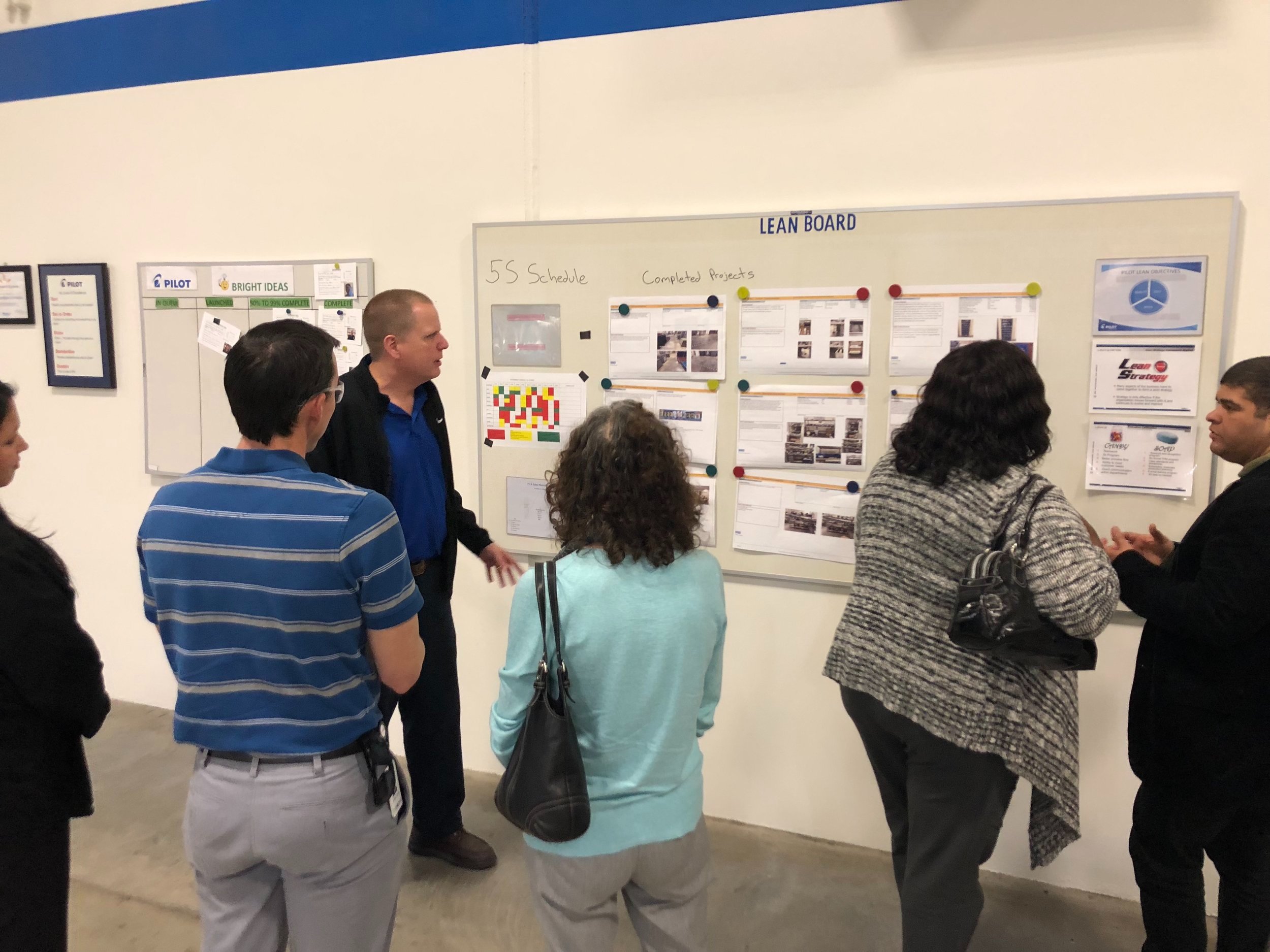

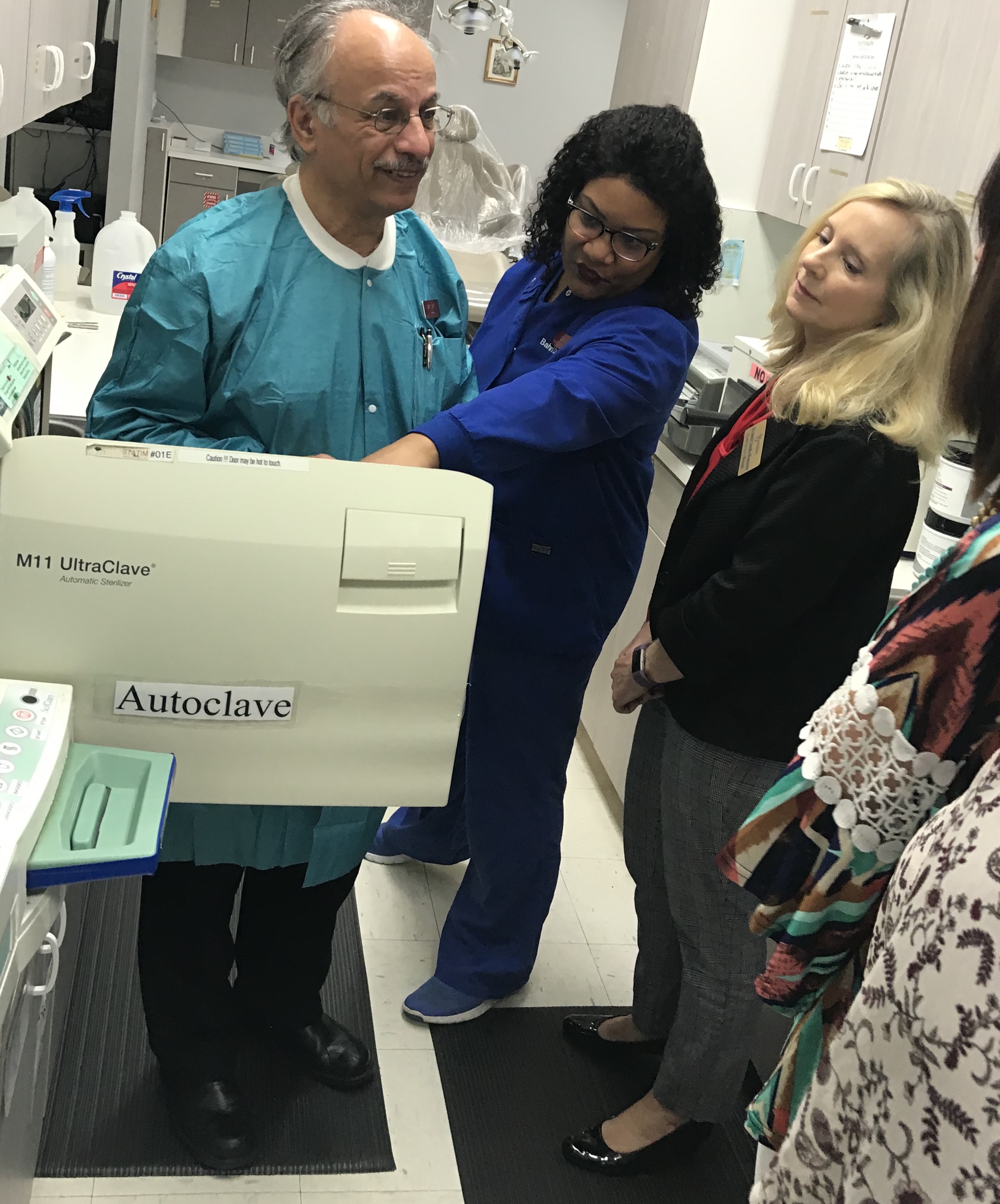

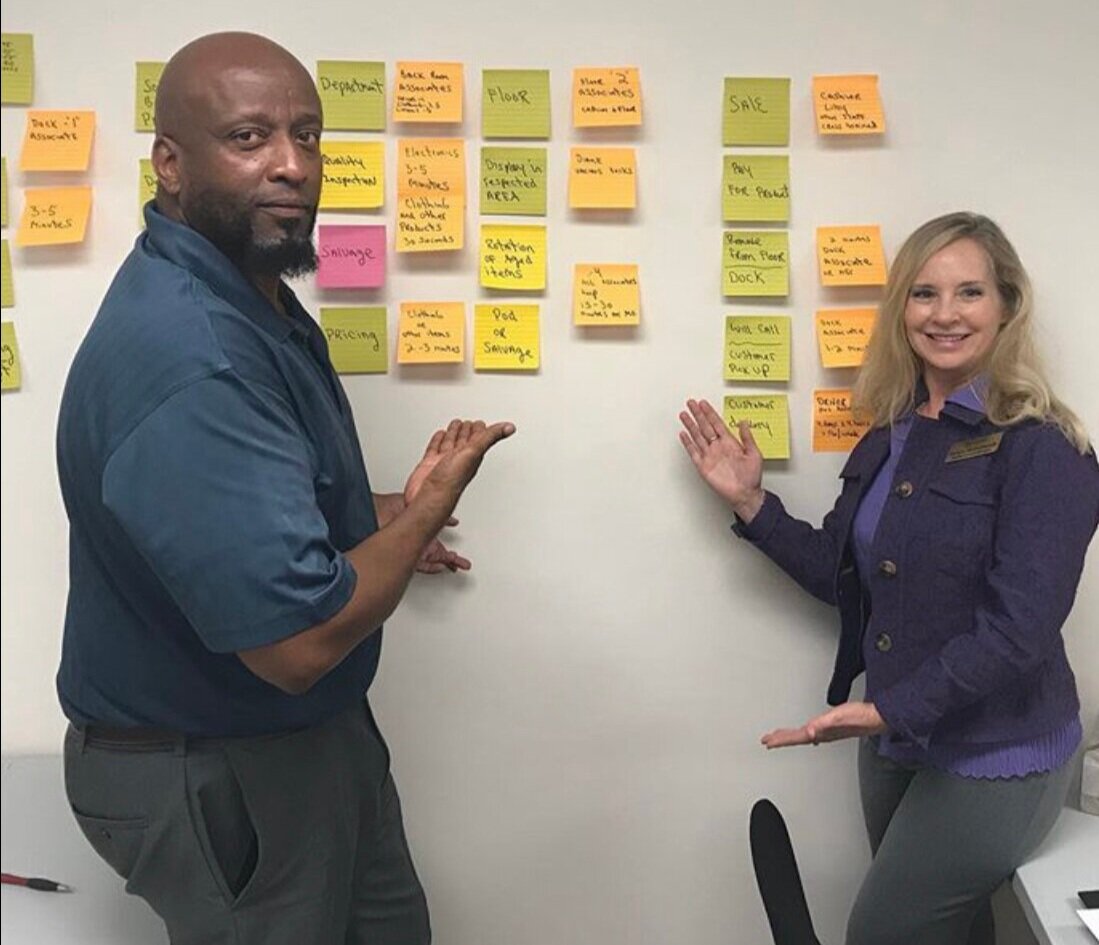

✅ A Lean leader meeting is a collaborative, benchmarking event that brings together key leaders and stakeholders from organizations applying Lean thinking and practice. These meetings are essential for seeing lean principles in action, learning from real-world applications, sharing valuable insights, solving problems, and building a support network for your lean journey.

✅Visit our members and “Go see” Lean Thinking and Practice in action!

✅ Benchmark best practices, share knowledge, and learn from our members!

✅ Implement Lean systems and methods; improve key value streams; solve critical problems; share your learning; and raise the improvement bar!

Lean Leader Meeting Costs

Lean Jax Members: FREE for up to ten (10) employees per visit. $25 for each additional employee.

Non-members: $75 per employee per visit.

IV. Member Resources Page and Lean Starter Pack

Offered exclusively to all Lean Jax members, included in our annual membership dues.

Our Member Resources page is updated weekly and includes: Lean Starter Pack, templates, Lean transformation guides, instructions for all components of Lean playbook, standard work documentation, glossaries, training presentations, member examples, Lean certification projects, links to videos, case studies, white papers, and more!

V. Lean Transformation Support

Assistance in developing annual Lean transformation charter. (All Levels)

Lean Jax Virtual Office Hours (All Levels)

Strategy Deployment (Included in Platinum and Gold)

Annual Lean transformation Assessment (Included in Platinum, Gold, and Silver)

Value Stream Mapping guidance, preparation, facilitation, and follow-up (Included in Platinum, Gold, and Silver)

Rapid Improvement Event (“RIE”) preparation, facilitation, and follow-up (Included in Platinum and Gold)

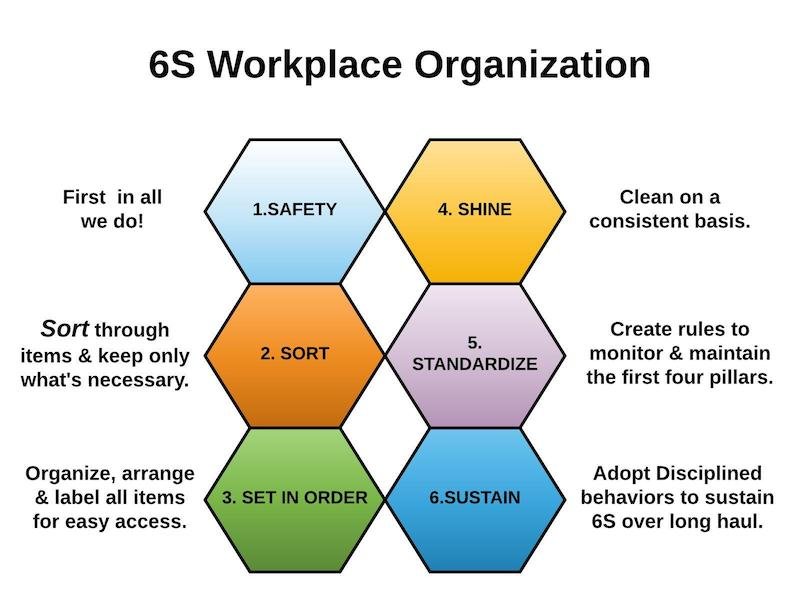

6S Workplace Organization Event (Included in Platinum and Gold)

VI. Lean Certification Training

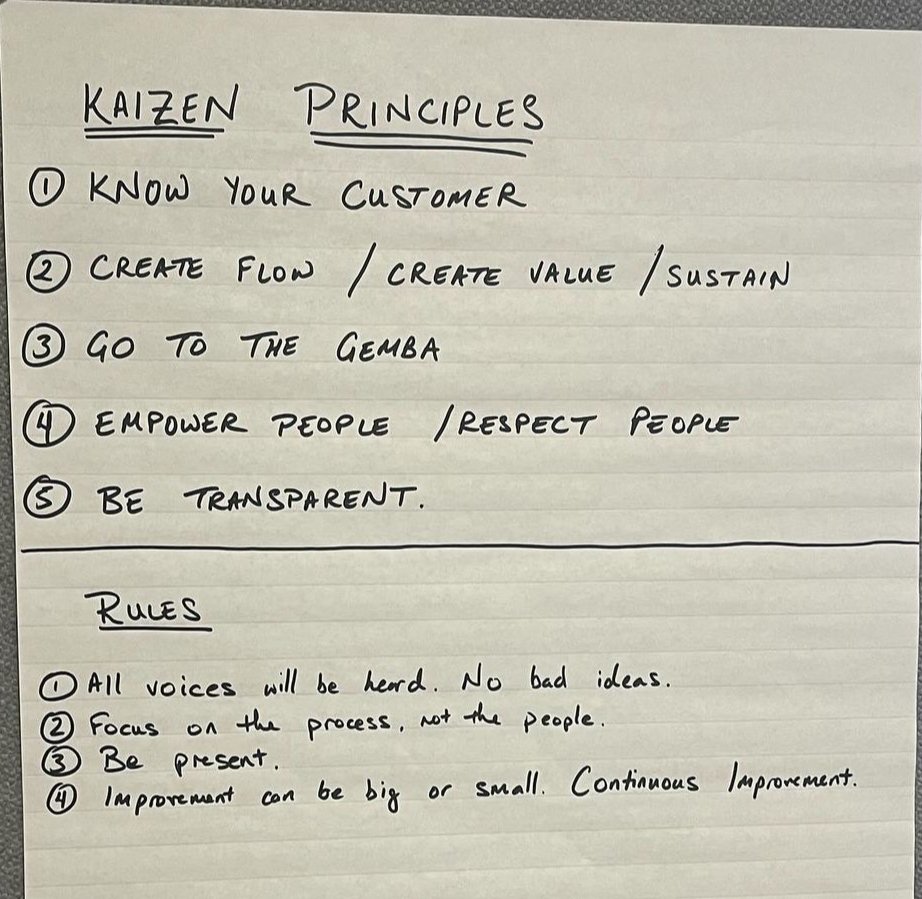

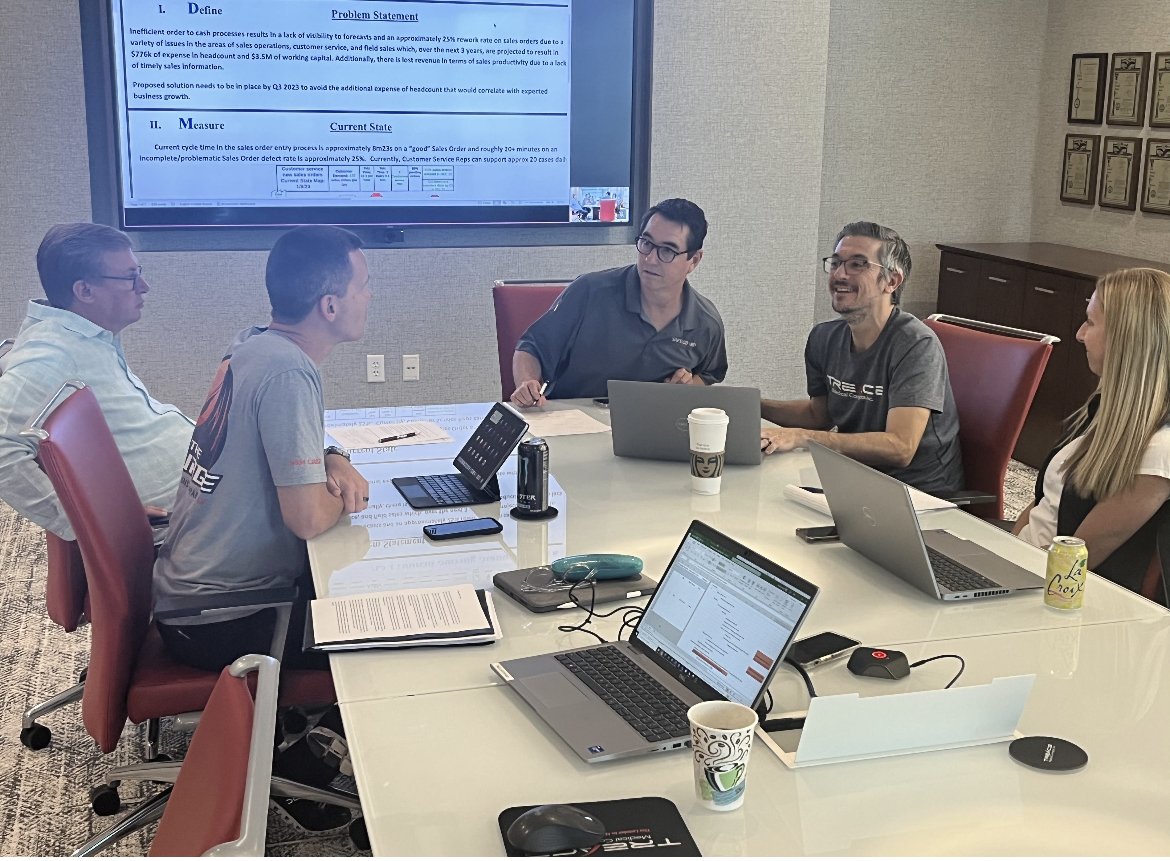

✅ Gain the foundational Lean knowledge and skills to identify and eliminate waste, enhance process performance, solve problems, and deliver tangible results.

✅ This certification equips you to lead daily huddles, conduct cross-functional value stream mapping, and contribute significantly to rapid improvement events. As a Lean Practitioner, you'll drive continuous improvement, embrace experimentation, and create exceptional value for customers.

Certification Training Series Cost

Lean Jax Members: $1,700 per attendee

Non-members: $2,500 per attendee

Additional Details

The next training series with participants from multiple organizations will start in April 2025.

We offer this training on-site for companies who register a minimum of five (5) attendees. Representatives from interested companies, schedule a free virtual consultation:

✅ Gain the in-depth Lean knowledge and skills necessary to lead and facilitate Lean improvement projects across multiple departments. This certification equips you to facilitate daily huddles, meetings, cross-functional value stream mapping, and rapid improvement events.

✅ As a Lean Facilitator, you'll champion collaboration, drive tangible process improvements, and enrich the work environment while creating exceptional value for customers. Additionally, you will develop the capability to transfer knowledge and instruct others at all levels of the organization on Lean principles, methods, and culture, while also possessing strong systems thinking abilities to understand the interconnectedness of value streams and departments.

Lean Facilitator Certification Training Cost

Lean Jax Members: $3,000 per attendee

Non-members: $4,000 per attendee

Additional Details

❇️ We offer training workshops on-site for companies that register a minimum of three (3) attendees. Interested companies, please reach out to us to set up a free consultation to coordinate logistics:

VII. Additional Lean Advisory Services

James Bussell provides customized, enterprise-wide Lean transformation advisory services upon request. Lean Jax members receive a discounted rate. This includes:

☑️ Enterprise-wide Lean Transformation Guidance and Support.

☑️ Customized Lean Transformation Strategy Development and Deployment Support.

☑️ Lean Operating and Management System Development and Implementation Support.

☑️ Lean Model Line Implementation and Replication in Additional Areas.

☑️ 6S, Standardized Work, and Visual Management Systems Implementation.

☑️ Employee Suggestion System Implementation.

☑️ Kaizen Event Facilitation (3-4 Full Days).

☑️ Tailored, On-site Lean Facilitator Certification Training.

☑️ One-on-one Lean Leadership Coaching and Certification for Executive, Management, and Supervisor Levels.