Only 48 hours left to register for our May 3 Virtual Workshop: Eliminate the 8 Wastes with Lean Thinking!

Topic

Eliminate the 8 Wastes with Lean Thinking Workshop

Date

Friday, May 3, 2024

Time

9:00 AM-12:00 PM

Location

Via Zoom

Instructor

James Bussell

Cost

Free for Lean Jax members; $75 for non-member attendees

Register here:

https://jlc.wildapricot.org/event-5664138

Workshop Overview

One of the primary objectives for lean practitioners and enterprises is to to smoothly flow value to our customers by eliminating waste—any task/activity that consumes resources yet creates no customer value.

No matter the type of business, waste is prevalent—often accounting for 90% or more of the time it takes to complete a process, causing endless headaches along the way. Fortunately, this doesn't have to be the case. We can conquer waste and create smoothly flowing value streams. Lean thinking is the way.

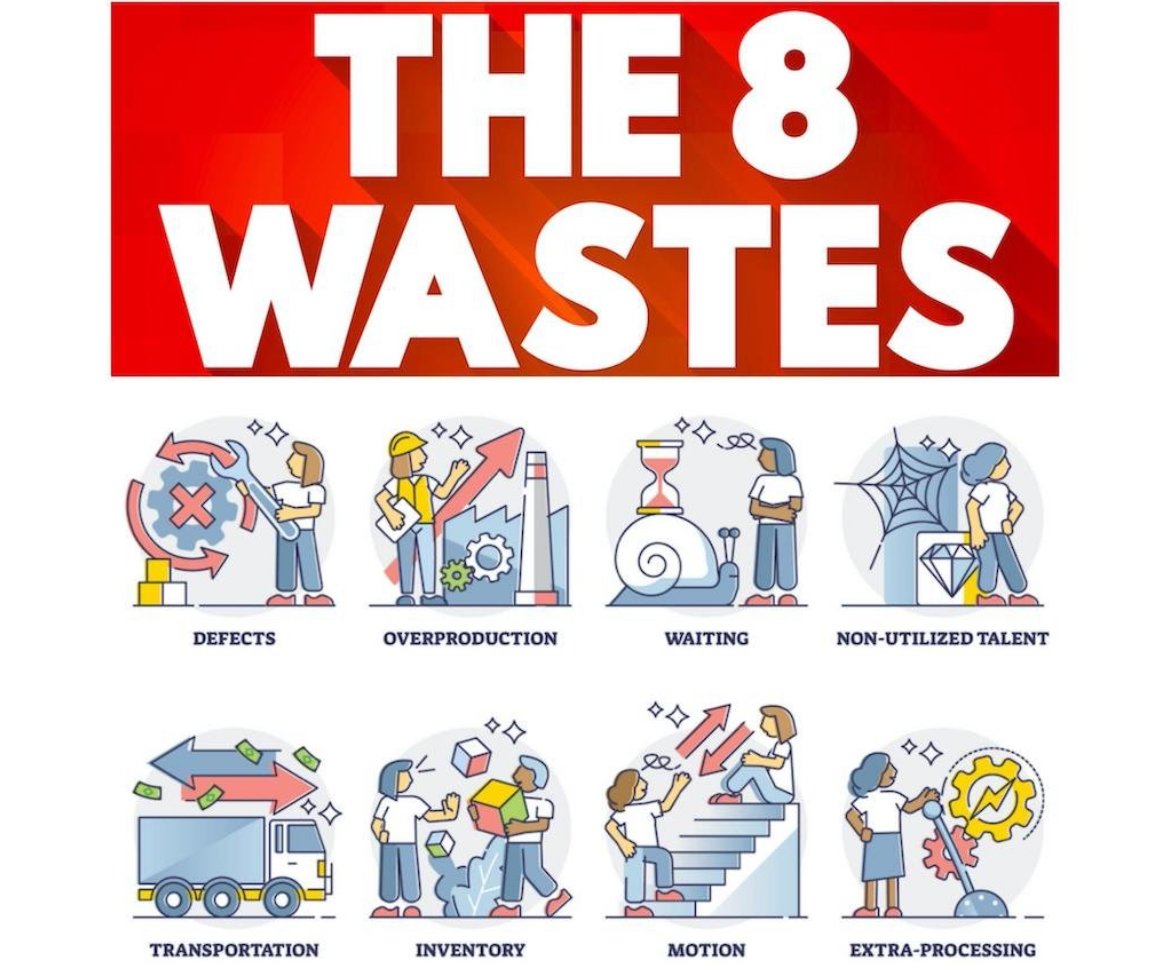

By participating in this workshop, attendees will learn how to identify, eliminate, and prevent the 8 major categories of waste from frustrating our customers, draining our resources, and damaging our businesses.

Through engaging discussions, interactive exercises, and real-life case studies, this workshop is designed to provide attendees with the knowledge and skills to eliminate waste and drive improvement throughout their organizations.

Whether you're a seasoned practitioner or new to the world of Lean, a manufacturer or a virtual worker, an intern or a CEO, this training event is designed to inspire and empower.

Workshop Outline

Value-Added Work vs. Non-Value-Added Work: Distinguishing between necessary work and waste.

Toast Kaizen Video and Discussion: Learning from real-world applications of lean thinking.

8 Wastes Overview: Definitions, examples, and outcomes.

Waste Identification Exercise: Hands-on practice in spotting waste.

Benefits of Waste Elimination: Case studies on the real-world impact of lean practices.

Waste Identification Techniques: Using gemba walks, spaghetti diagrams, and fishbone diagrams.

Waste Elimination Methods: Introduction to ECRS, mistake-proofing, setup reduction, standard work, and 6S workplace organization.

Next Steps: Guiding participants on how to continue their lean journey.

Summary

Don't miss this opportunity to gain invaluable insights and practical strategies that will transform your work. If you can't make it this time out, we will offer this training every quarter.

It doesn't take a superhero to identify and eliminate waste, but coming to work each day with a continuous improvement mindset provides a comparable impact.